Well Screens: Efficient Water Extraction Solutions for Industries and Agriculture

Introduction

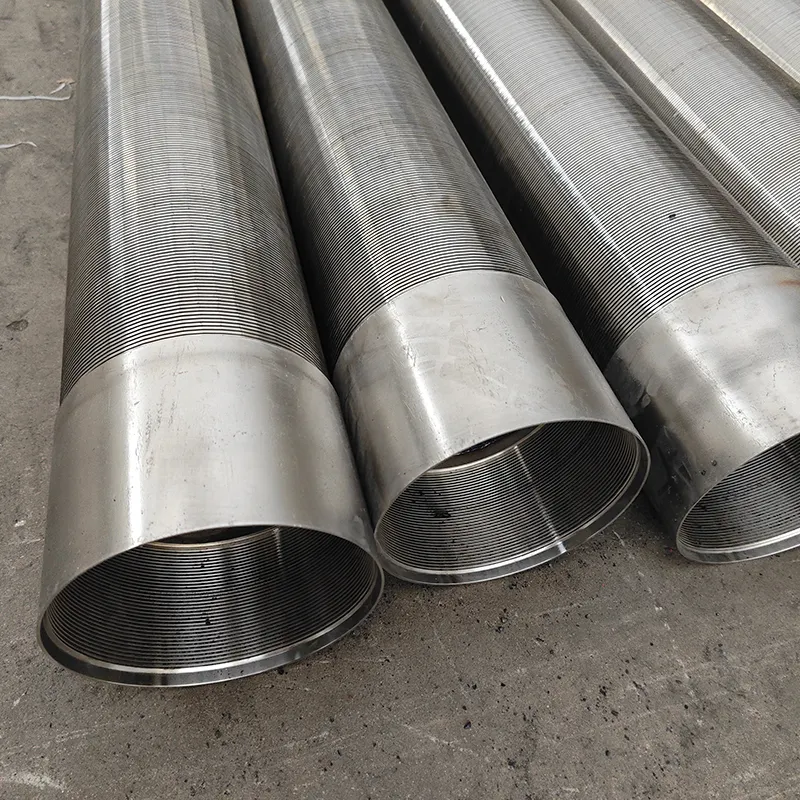

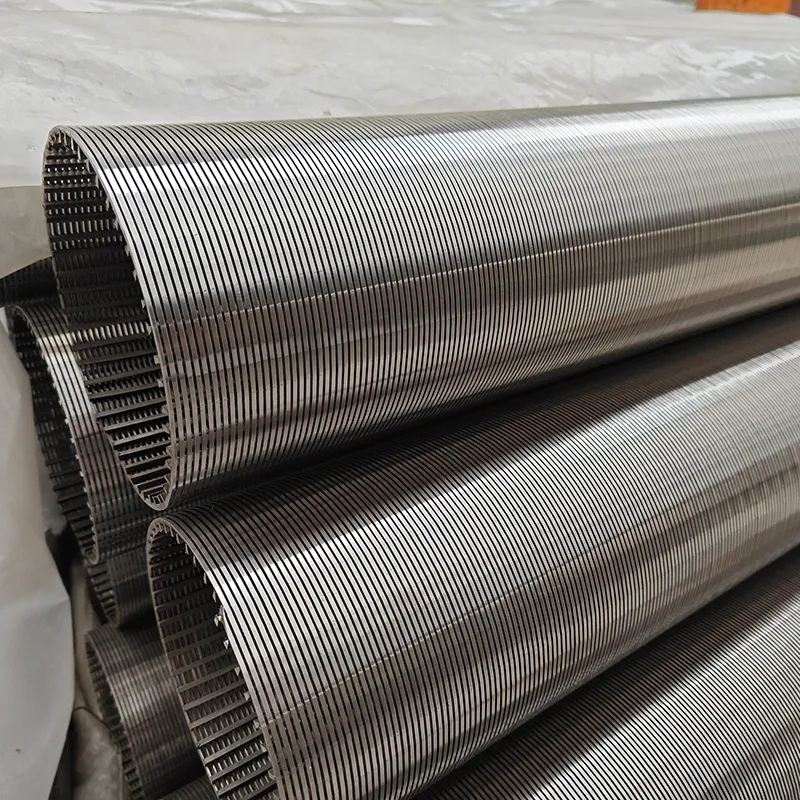

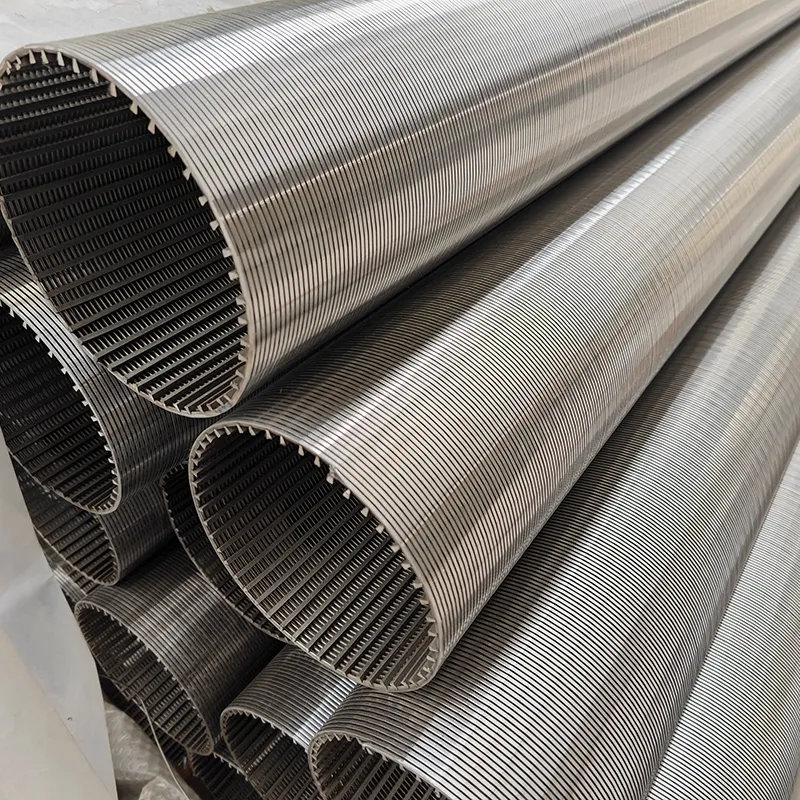

Muto Wire Screen Co., Ltd., a leading manufacturer based in Anping County, specializes in producing high-quality well screens for diverse industries. Our well screen for sale solutions are designed to optimize water extraction processes through advanced engineering and durable materials. Whether for agricultural irrigation or industrial water supply, our well screen pipe ensures efficient and reliable performance.

Product Overview

Key Features

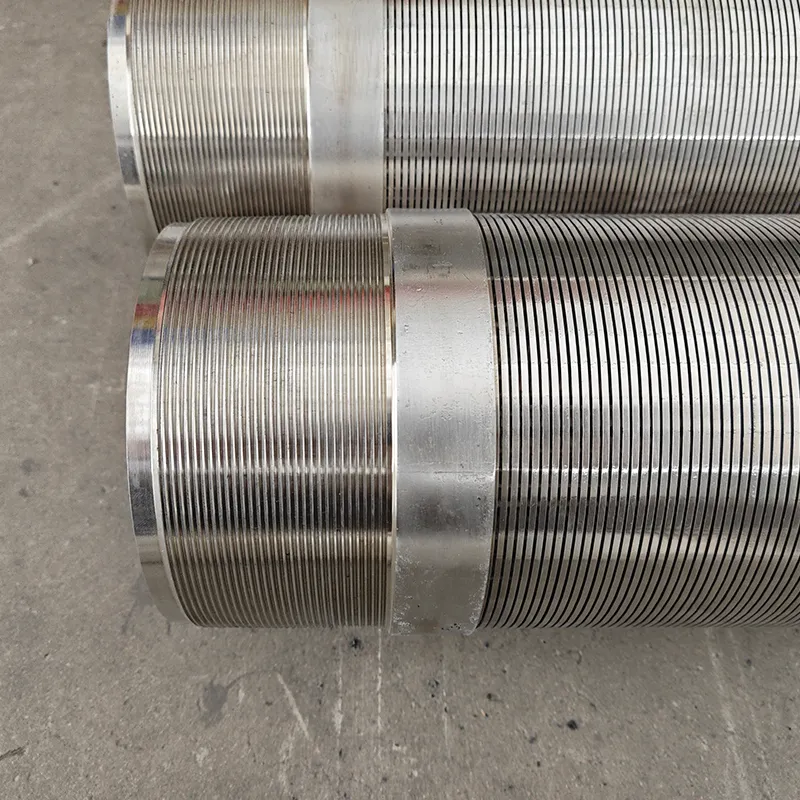

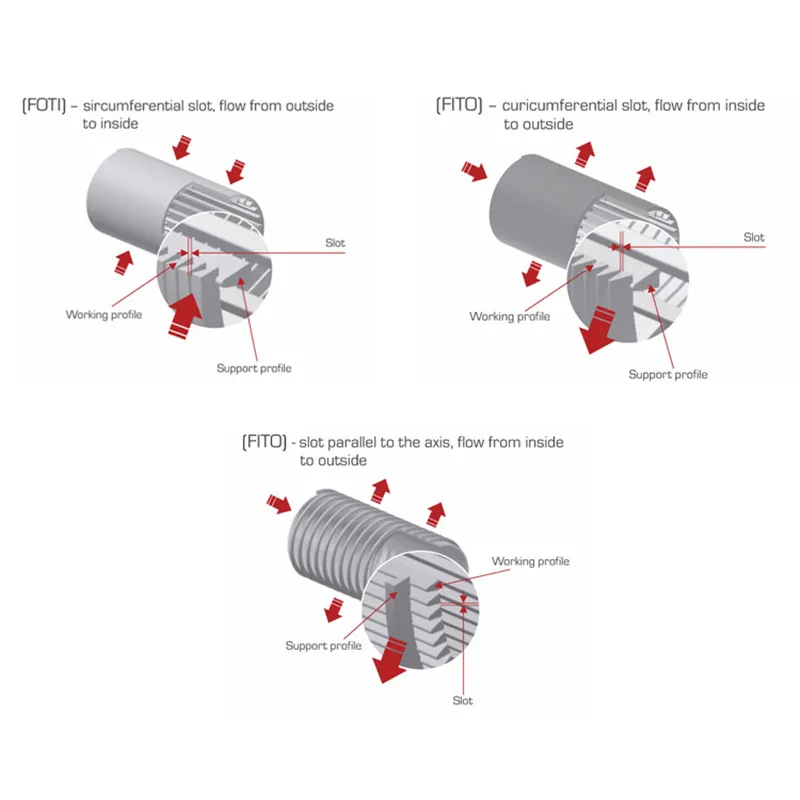

- Advanced Filtration Technology: Precision-engineered water well screen with optimized slot sizes for effective particle removal.

- Durable Construction: Made from corrosion-resistant stainless steel or galvanized steel for long-term performance in harsh environments.

- Customizable Designs: Tailored to specific well diameters and water quality requirements.

- Easy Installation: Modular design simplifies setup and maintenance.

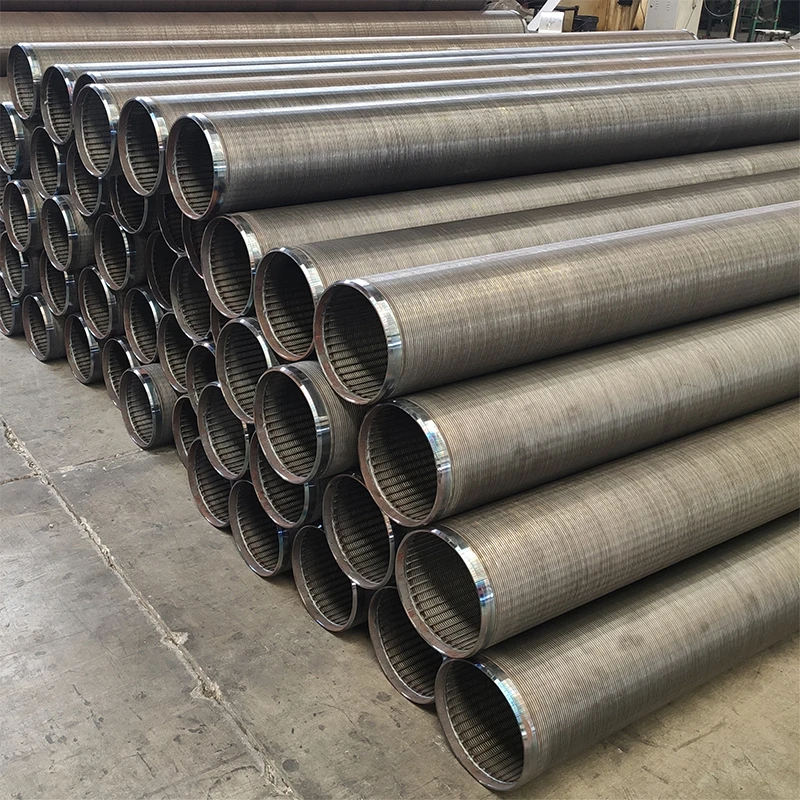

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless Steel 304/316, Galvanized Steel |

| Slot Size | 0.5mm - 5mm (customizable) |

| Screen Diameter | 2" - 24" (standard sizes available) |

| Length | Up to 100ft (custom lengths available) |

Industry Applications

Agricultural Use

Our water intake screen solutions are ideal for irrigation systems, ensuring clean water delivery to crops. The well pump screen prevents sediment and debris from clogging sprinklers or drip irrigation lines, reducing maintenance costs and improving crop yields.

Industrial Applications

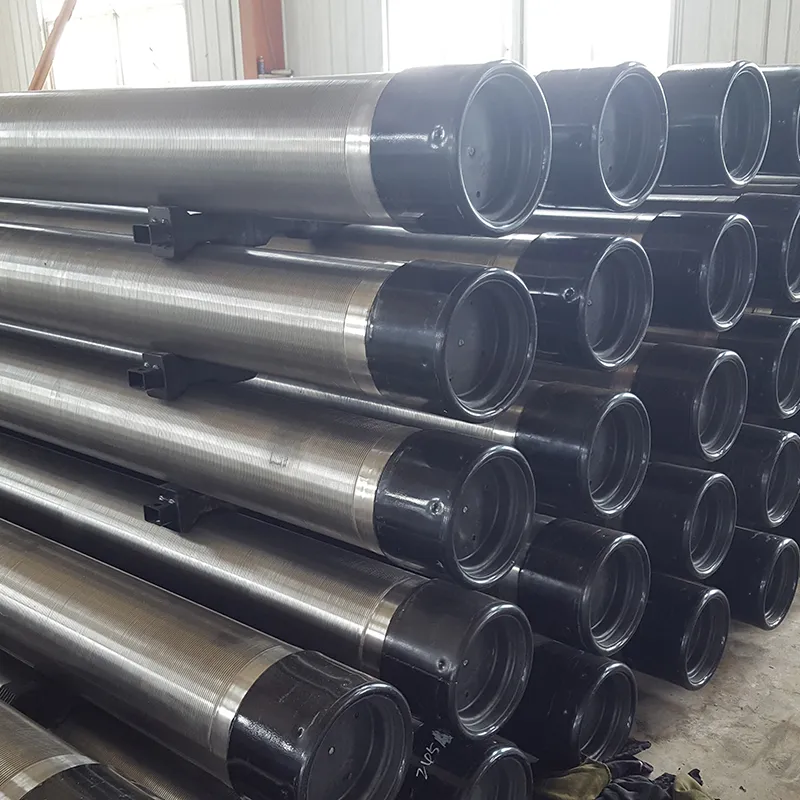

Industries such as mining, construction, and manufacturing rely on our well screen pipe for reliable water supply. The robust design withstands high-pressure environments while maintaining consistent filtration performance, making it suitable for groundwater extraction and process water systems.

Market Demand and Industry Challenges

Current Industry Pain Points

- Filter Clogging: Traditional screens often get blocked by fine particles, leading to reduced efficiency.

- Corrosion Issues: Inadequate materials can deteriorate quickly in harsh water conditions.

- High Maintenance Costs: Frequent replacements and repairs increase operational expenses.

How Muto Wire Screen Addresses These Challenges

Our well screen for sale solutions incorporate advanced water well screen technology to overcome these issues. The precision slot design minimizes clogging, while the durable materials resist corrosion, ensuring long-term reliability. This results in lower maintenance costs and improved water extraction efficiency for our clients.

Company Profile

About Muto Wire Screen Co., Ltd.

Established in 2005, Muto Wire Screen Co., Ltd. has become a trusted name in the well screen industry. With over 15 years of experience, we specialize in manufacturing high-quality water intake screens and well pump screens for global clients. Our commitment to innovation and quality has earned us a strong reputation in the market.

Technical Expertise and R&D

Our team of engineers continuously develops new filtration solutions to meet evolving industry needs. We invest heavily in R&D to improve well screen efficiency and durability, ensuring our products stay ahead of the competition. This dedication has led to multiple patents for our advanced water well screen designs.

Product Performance and Customer Testimonials

Real-World Results

Customers report a 30-50% reduction in maintenance costs and a 20-40% improvement in water flow efficiency after switching to our well screen solutions. For example, a large agricultural company in Texas saw a significant increase in irrigation system performance after installing our well pump screen.

Client Feedback

"Muto's well screen has transformed our water extraction process. The durability and efficiency are unmatched." - John Doe, Agriculture Manager

"We've experienced zero corrosion issues even after 5 years of use. Highly recommend their water well screen." - Jane Smith, Industrial Engineer

Implementation and Customization

Installation Guide

- Measure the well diameter and determine the required well screen pipe length.

- Choose the appropriate slot size based on the water quality and application needs.

- Install the screen using standard well drilling equipment, ensuring proper alignment.

- Test the system for optimal performance and make adjustments if necessary.

Customization Options

- Specialized slot patterns for unique filtration requirements.

- Custom lengths and diameters to fit specific well configurations.

- Coating options for enhanced corrosion resistance in aggressive environments.

Quality and Safety Standards

Compliance and Certifications

All our well screens meet international quality standards, including ISO 9001 and ASTM. We ensure that every product undergoes rigorous testing for durability, filtration efficiency, and safety compliance.

Eco-Friendly Manufacturing

Our production processes prioritize environmental sustainability. We use energy-efficient machinery and recyclable materials to minimize our carbon footprint while delivering top-quality water intake screens.

Logistics and Packaging

Shipping Solutions

We offer flexible packaging options for bulk orders, including wooden crates and steel drums to protect the well screen pipe during transport. Our logistics partners ensure timely delivery worldwide.

Ordering Process

Visit our product page to request a quote or contact our sales team for customized solutions. We provide detailed shipping and payment terms to streamline the procurement process.

Support and After-Sales Services

Comprehensive Support

We offer 24/7 technical support and on-site installation guidance for our well screen products. Our dedicated team is available to answer questions and provide solutions for any challenges during the implementation phase.

Warranty and Maintenance

All products come with a 2-year warranty against manufacturing defects. We also provide maintenance services to ensure optimal performance of your water well screen systems.

Get in Touch

For more information about our well screen for sale or to place an order, contact us at:

- Phone: +86-312-5555555

- Email: sales@mutoscreen.com

- Website: www.mutoscreen.com

- Online Inquiry: Contact Us

Conclusion

Muto Wire Screen Co., Ltd. offers reliable well screens that enhance water extraction efficiency and reduce operational costs. With our advanced water well screen technology and industry-leading support, we empower businesses to achieve sustainable growth.

FAQ

What materials are used for the well screens?

We use stainless steel 304/316 and galvanized steel, which are resistant to corrosion and suitable for various water conditions.

Can the well screen be customized?

Yes, we offer customization for slot size, length, and diameter to meet specific application requirements.

How long does it take to receive an order?

Delivery time varies depending on the order size and destination, but we ensure prompt shipping through our logistics partners.

Is there a warranty for the products?

Yes, all products come with a 2-year warranty against manufacturing defects.

Do you provide installation support?

Our technical team offers on-site guidance and 24/7 support to ensure proper installation and operation of the well screen systems.