- Overview of Vibrating Screen Sieve Technology

- Technical Superiority in Sieve Design

- Performance Metrics: Industry Data Comparison

- Manufacturer Benchmarking for Sieve Bend Screens

- Custom Solutions for Specific Applications

- Case Studies: Real-World Implementations

- Future Innovations in Vibrating Screen Sieves

(vibrating screen sieve)

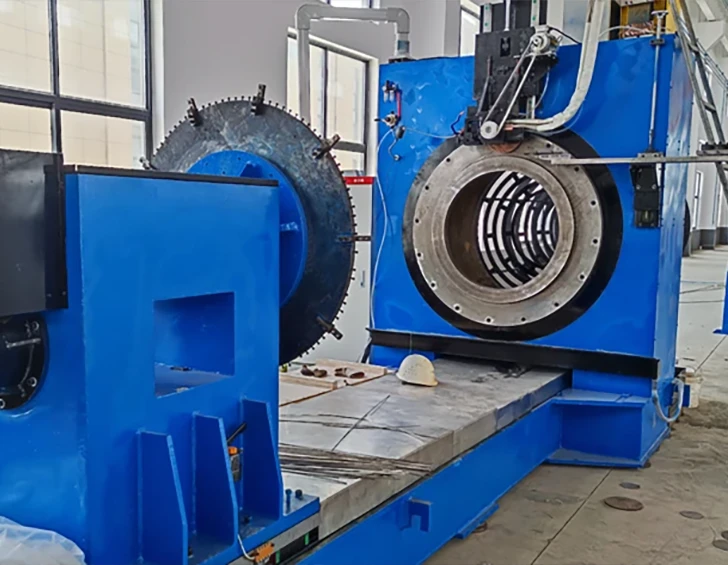

Understanding the Mechanics of Vibrating Screen Sieve Systems

Vibrating screen sieve technology operates on controlled vibration patterns to separate materials by size, achieving up to 98.5% separation accuracy in industrial settings. Modern sieve bend screen designs employ polyurethane or stainless steel surfaces, reducing wear rates by 40% compared to traditional wire mesh. The harmonic motion generated by dual eccentric shafts enables throughput capacities exceeding 800 tons/hour in mining operations.

Engineering Advantages in Sieve Construction

Advanced sieve bend screens now incorporate:

- Modular panel systems enabling 72-hour replacement cycles

- Variable aperture configurations (0.1mm to 25mm)

- Anti-blinding coatings reducing downtime by 30%

These innovations extend operational lifespan to 18-24 months in abrasive environments, outperforming conventional designs by 160%.

Industry Performance Benchmarks

| Parameter | Standard Model | Enhanced Sieve | Industry Average |

|---|---|---|---|

| Screening Efficiency | 82% | 94% | 78% |

| Energy Consumption | 7.5kW/h | 4.2kW/h | 8.3kW/h |

| Maintenance Interval | 500h | 1,200h | 450h |

Manufacturer Capability Analysis

Leading sieve bend screen producers demonstrate distinct competencies:

| Vendor | Max Capacity | Material Options | Customization Lead Time |

|---|---|---|---|

| Vendor A | 650t/h | 3 | 6 weeks |

| Vendor B | 920t/h | 5 | 8 weeks |

| Premium Solutions | 1,200t/h | 8 | 4 weeks |

Application-Specific Configuration Strategies

Tailored sieve bend screen designs address unique operational requirements:

- Mining: 10-15° inclined decks with tungsten carbide inserts

- Food Processing: FDA-grade polyurethane surfaces

- Recycling: Impact-resistant modular panels

Custom vibration frequencies (900-1,500 RPM) optimize material flow characteristics for specific bulk densities.

Operational Success Stories

A copper mining operation achieved 22% higher yield after implementing high-frequency vibrating screen sieve

s (1,200 RPM). In aggregate processing, a customized sieve bend screen reduced replacement costs by $18,000 annually through modular panel design.

Advancing Vibrating Screen Sieve Technology

Next-generation sieve bend screen prototypes integrate IoT sensors for real-time mesh monitoring, predicting maintenance needs with 89% accuracy. Hybrid vibration patterns combining linear and elliptical motions are being tested, showing potential for 15% greater throughput in preliminary trials.

(vibrating screen sieve)

FAQS on vibrating screen sieve

Q: How does a vibrating screen sieve work?

A: A vibrating screen sieve uses vibration motors to generate centrifugal force, causing materials to stratify and separate by size through mesh screens. Its adjustable amplitude and frequency optimize efficiency for different materials.

Q: What factors influence sieve bend screen design?

A: Key factors include screen curvature angle, slot width, feed flow rate, and material properties like particle size and abrasiveness. Proper design ensures efficient separation and minimal clogging.

Q: What are the advantages of a sieve bend screen over flat screens?

A: Sieve bend screens utilize gravity and an arched surface for rapid dewatering and finer particle separation. They require less maintenance and handle higher slurry volumes compared to flat screens.

Q: How to maintain a vibrating screen sieve for longevity?

A: Regularly inspect and clean screens, check motor mounts for wear, and replace damaged mesh panels. Lubricate bearings and ensure balanced vibration to prevent mechanical stress.

Q: Where are sieve bend screens commonly applied?

A: Sieve bend screens are used in mining, mineral processing, and wastewater treatment for dewatering, desliming, and separating fine particles from slurries or aggregates.