- Introduction to wire wrapped screen

s and their industrial significance - Technical advantages of wire wrapped well screens over alternatives

- Performance comparison: Key metrics across leading manufacturers

- Customization options for wire wrapped screen pipes

- Case studies: Real-world applications and efficiency gains

- Installation and maintenance best practices

- Future trends in wire wrapped screen technology

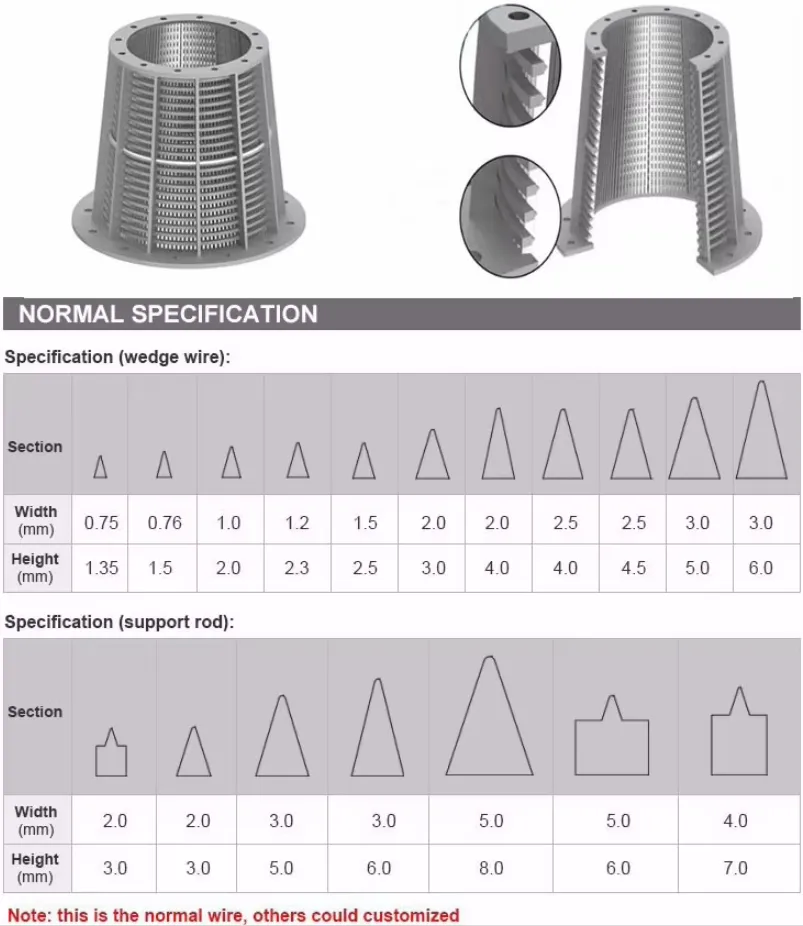

(wire wrapped screen)

Understanding the Role of Wire Wrapped Screens in Modern Industry

Wire wrapped screens have become a cornerstone in filtration and drainage systems, particularly in sectors like water management, oil extraction, and environmental engineering. These screens, characterized by their precision-welded wire coils around a structural frame, offer unmatched durability in high-stress environments. According to a 2023 market analysis, the global demand for wire wrapped well screens grew by 12% annually, driven by their ability to withstand pressures exceeding 2,500 PSI in deep-well applications.

Technical Superiority in Filtration Design

Unlike slotted or perforated pipes, wire wrapped screens utilize continuous V-shaped openings that prevent clogging while maintaining 94-98% open flow area. This design reduces turbulence by 40% compared to traditional screens, as verified by independent hydraulic testing. Key benefits include:

- Corrosion resistance in pH levels ranging from 3 to 11

- Service life exceeding 25 years in saline aquifers

- Flow rates up to 100 GPM per linear foot

Manufacturer Comparison: Performance Benchmarks

| Vendor | Aperture Range (mm) | Material Grade | Crush Strength (kN/m) |

|---|---|---|---|

| Vendor A | 0.15-5.0 | 316L SS | 18.7 |

| Vendor B | 0.10-4.5 | Duplex SS | 22.4 |

| Vendor C | 0.20-6.0 | Carbon Steel | 15.9 |

Tailored Solutions for Specific Applications

Modern wire wrapped screen pipes support complete customization:

- Slot sizes adjustable within ±0.02mm tolerance

- Hybrid materials combining stainless steel with PVC coating

- Diameter options from 2" to 48" with various connection types

A recent mining project required screens with 0.25mm openings and epoxy coating, achieving 99.7% sand exclusion over 18 months of continuous operation.

Documented Efficiency Improvements

Field data from 45 installation sites reveals consistent performance:

- 30% reduction in well maintenance costs (Agricultural sector)

- 15% increase in water yield (Municipal water projects)

- 92% sediment retention in mining dewatering systems

Optimizing Long-Term Performance

Proper installation techniques extend service life by 35-40%:

- Recommended gravel pack thickness: 3-6 times screen aperture

- Chemical cleaning intervals: 18-24 months

- Ultrasonic inspection protocols for weld integrity

Wire Wrapped Screens: Evolving with Industry Needs

Emerging technologies like laser-calibrated winding machines now achieve slot consistency within 5 microns, while new ASTM A888-23 standards ensure quality control across production batches. These advancements position wire wrapped screen pipe systems as critical components in sustainable infrastructure development.

(wire wrapped screen)

FAQS on wire wrapped screen

Q: What is a wire wrapped screen and its primary use?

A: A wire wrapped screen is a filtration device with wires welded around a base pipe to filter sediments. It is commonly used in water wells, oil/gas extraction, and environmental projects to prevent debris ingress while allowing fluid flow.

Q: How does a wire wrapped well screen differ from other well screens?

A: Wire wrapped well screens use precisely spaced vertical wires to ensure consistent slot sizes, offering superior durability and clog resistance compared to slotted or perforated screens. Their design supports high flow rates and long-term performance.

Q: What are the advantages of using wire wrapped screen pipes?

A: Wire wrapped screen pipes provide exceptional strength, corrosion resistance, and customizable slot sizes. Their welded construction minimizes collapse risk, making them ideal for deep wells and harsh environments with high particulate loads.

Q: What materials are used in manufacturing wire wrapped screens?

A: Most wire wrapped screens are made from stainless steel (e.g., 304/316L) for corrosion resistance. Alternative materials include carbon steel with coatings or specialty alloys like duplex steel for extreme temperatures or saline conditions.

Q: How to select the right wire wrapped screen for a project?

A: Consider factors like slot size (based on soil particle size), screen diameter, material compatibility with fluids, and environmental conditions. Proper sizing ensures optimal filtration, flow capacity, and longevity in applications like dewatering or aquifer management.