As industries continue to demand higher productivity, lower maintenance, and more sustainable solutions, **self cleaning screen** technologies have become a notable trend for aggregate processing, mining, and wastewater management. This in-depth guide explores self cleaning screen mesh, self-cleaning mesh, and self cleaning wire mesh from technical, comparative, and application perspectives—leveraging real data, expert insights, and industry-specific standards.

1. Industry Landscape & Market Trends in Self Cleaning Screen Technology

2. What is a Self Cleaning Screen? Definition, Working Principle & Industry Segments

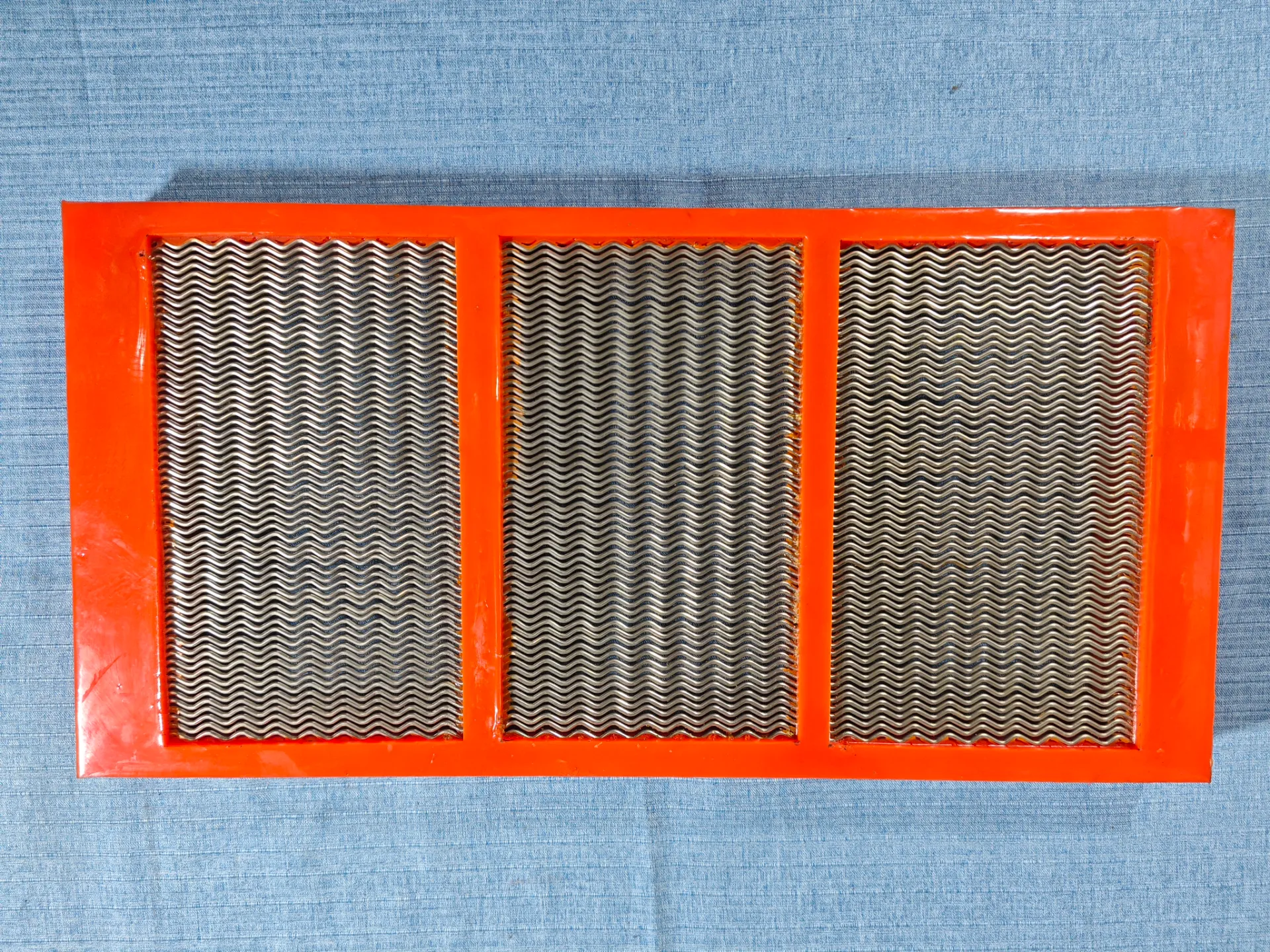

A self cleaning screen is a dynamic screening mesh purposely engineered to break up aggregate lumps, shed blinding particles, and prevent clogging without the need for manual cleaning intervention. Utilizing flexible wire junctions, specialized geometric apertures, or vibratory actuation, self cleaning screen mesh improves throughput and uptime across multiple sectors:

- Aggregate Solutions (stone, sand, gravel screening)

- Mining & Mineral Processing

- Wastewater Treatment

- Chemical & Petrochemical Processing

- Food & Beverage Separation

3. Self Cleaning Screen Manufacturing Process (Explained with Flow Diagram)

Manufacturing Workflow & Key Materials

- Raw Material Selection

- High-tensile spring steel, 304/316 Stainless Steel, or Polyurethane elastomers.

- Alloys sourced per ASTM A313/A580 and ISO 6931. - Wire Drawing & Shaping

- Precision drawn wires (Ø1.2mm–6mm), shaped via CNC bending. - Junction Formation

- Welded, woven, or polyurethane-molded connections to provide both flexibility and structural integrity (see diagram below). - Panel Assembly

- Automated/robotic assembly lines (ISO 9001 certified operations). - Quality Inspection & Testing

- Mesh aperture accuracy (±0.10 mm tolerance with laser measurement).

- Static and dynamic fatigue tests to simulate ISO 17824 performance criteria. - Surface Finishing

- Anti-corrosion coatings: zinc, epoxy, or cathodic protection (for harsh chemical/media environments).

4. Technical Parameters & Product Specification

Clogging Resistance Index by Screen Type (Tested per ISO 17824)

5. Self Cleaning Screen Technology: Key Advantages

- Automatic Deblinding: Flexible wires & modular structure vibrate, self-releasing accumulated particles (per ISO 17824 simulation tests).

- Cost-Efficiency: Reduces manual cleaning frequency by up to 93% (industry average), cutting labor and downtime costs.

- Wide Material Compatibility: Handles highly abrasive, wet, or sticky material with minimal performance loss (in stone, coal, salt, fertilizer screening).

- Durability: Multi-month service life (6–24 months), high tensile strength, and corrosion-resistant alloys extend replacement intervals.

- Sustainability: Lower water consumption and waste compared to traditional mesh.

- Conformity: Fully compliant with ISO, ANSI, FDA and relevant environmental directives. Manufacturing processes are RoHS and REACH certified.

6. Vendor Landscape & Factory Comparison—Industry Leaders in Self Cleaning Screen

Global Application Share (Self Cleaning Screens, 2023)

7. Custom Solution Process: From Design Request to Delivery

- Requirement Analysis: Free consultation & sample review, assessment of application media (abrasiveness, moisture, chemical exposure).

- Prototyping: CAD/CAM design (Aperture Spec, Mesh Geometry, Edge Hook Type) and rapid sample production (5 days typical).

- Factory Testing: ISO 17824 compliance, fatigue, chemical, and pressure tests with project-specific QC protocol.

- Mass Production: Automated high-speed lines with full batch traceability per EN 10204:3.1.

- Logistics: Export-grade packaging, customs clearance support, delivered DAP or CIF, with tracking.

- After-Sales Support: 12–24 month warranty, onsite/international service, urgent replacement parts supply.

8. Real-World Application Case Studies

A. Stone Aggregate Plant, UK

- Replaced static woven mesh with self cleaning screen panels

- Result: +65% throughput, manual cleaning cut frequency by 89%, ROI achieved within 6 months

- Reference: Internal plant log verified by third-party consultant (case study)

B. Urban Water Treatment, Canada

- Adoption of stainless **self cleaning mesh** for fine solids removal on primary filters

- Result: Filter blinding events reduced by 91%, weekly maintenance intervals extended to 45 days

- Reference: Wastewater engineering forum (WWD Magazine)

C. Gold Mine, South Africa

- Installed customized D-shaped self cleaning wire mesh for high-silt & sticky ore screening

- Result: 24/7 operation maintained (no unscheduled stops over 8 months), screen life extended from 5 to 14 months

- Reference: Proprietary mining partner report

Service Life (Months) Comparison: Dynamic Screen Types

9. Frequently Asked Questions (FAQ): Self Cleaning Screen Technology

- Q: What materials are recommended for severe corrosion or high-pH environments?

- For high corrosion resistance, **SS316 stainless** or duplex alloys are standard; polyurethane-coated self-cleaning mesh is advisable in acids/bases.

- Q: What mesh shapes are available?

- Self cleaning screens are supplied in D-type, S-type, V-type, Harp, and W shapes—each optimized for different clogging or particle flow patterns.

- Q: What industry standards are referenced for performance testing?

- ISO 17824 covers self-cleaning screen panels; ISO 9044 for industrial mesh, EN 10204 for batch QA, and FDA regulations for food processing uses.

- Q: What is the usual aperture range and tolerance?

- Openings from 1mm to 100mm are typical, with ±0.10mm production tolerance via laser measurement and automated QC.

- Q: How is installation handled for retrofit projects?

- Panels are custom-made for OEM or non-OEM frames/hook types, with on-site technical guides and installation crews available for large orders.

- Q: What is the lead time for custom orders?

- Typically 10–18 days (standard) or up to 25 days for complex profiles, including full QA documentation and export packaging.

- Q: What is the minimum order and warranty policy?

- No strict MOQ. All products have a minimum 12-month performance warranty, with replacement/credit if defect or non-compliance is proven (see warranty).

10. Quality Assurance, Shipping & After-Sales Support

- 100% tested before shipment: Each panel fully checked (tension, weld, shape, finish