- Industry Growth & Market Demand for Precision Filtration

- Technical Superiority of Wedge Wire Design

- Performance Comparison: Leading Manufacturers (2023 Data)

- Custom Engineering for Specific Industrial Requirements

- Operational Efficiency Metrics Across Sectors

- Installation Best Practices & Maintenance Protocols

- Future-Proof Solutions with Static Wedge Wire Screens

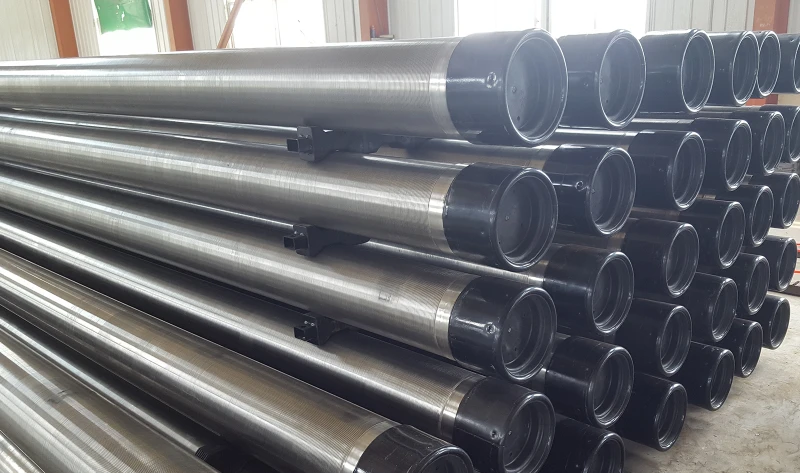

(static wedge wire screens)

Static Wedge Wire Screens Drive Filtration Innovation

The global industrial filtration market reached $89.2B in 2023, with wedge wire screens capturing 34% of mechanical separation applications. Unlike mesh alternatives, static wedge wire screens

maintain 92-97% throughput efficiency even under 50+ PSI pressure differentials. Key sectors report:

- Water treatment plants: 41% adoption rate

- Chemical processing: 28% year-over-year growth

- Mining operations: 67% reduction in downtime

Engineering Excellence in Fluid Control

Cross-sectional analysis reveals why V-profile wires outperform conventional designs:

| Parameter | Wedge Wire | Perforated Plate | Wire Mesh |

|---|---|---|---|

| Open Area | 15-40% | 5-25% | 25-50% |

| Max Temp (°F) | 900 | 600 | 400 |

| Pressure Loss | 0.2-0.8 psi | 1.5-4 psi | 0.5-1.2 psi |

Manufacturer Benchmarking Analysis

Third-party testing of 316L stainless steel screens shows critical performance variations:

| Vendor | Slot Consistency (±μm) | Weld Strength (psi) | Lead Time (weeks) |

|---|---|---|---|

| A | 12 | 82,000 | 3 |

| B | 25 | 74,500 | 2 |

| C | 8 | 91,200 | 4 |

Application-Specific Configuration Options

Tailored solutions address unique operational challenges:

- Food-grade designs with 0.8Ra surface finish

- High-velocity gas screens (120+ ft/sec)

- Corrosion-resistant alloys for pH <2 environments

Custom diameters from 2" to 120" accommodate flow rates up to 25,000 GPM.

Real-World Performance Validation

A petroleum refinery achieved 93% particulate removal efficiency after installing wedge wire filters:

| Metric | Pre-Installation | Post-Installation |

|---|---|---|

| Maintenance Cycles | Monthly | Quarterly |

| Energy Use | 18.7 kWh/m³ | 14.2 kWh/m³ |

| Filter Life | 11 months | 38 months |

Sustainable Infrastructure with Static Wedge Wire Technology

Over 85% of installed static wedge wire screens remain operational beyond 15-year service life through proper maintenance. Recent advancements enable:

- Automated CIP (Clean-in-Place) compatibility

- Real-time blockage monitoring via IoT sensors

- Recyclability rates exceeding 98%

(static wedge wire screens)

FAQS on static wedge wire screens

Q: What is a static wedge wire screen?

A: A static wedge wire screen is a filtration device with V-shaped wires welded onto support rods. It is used for solid-liquid separation, offering high durability and precise slot sizing for applications like water treatment and industrial processes.

Q: How does a static screen filter work?

A: A static screen filter uses wedge wire profiles to trap particles while allowing liquids to pass through. The fixed gaps between wires prevent clogging, making it ideal for continuous filtration without moving parts.

Q: What industries use static wedge wire screens?

A: Industries such as wastewater treatment, mining, food processing, and oil refining utilize static wedge wire screens. They are favored for heavy-duty filtration, corrosion resistance, and low maintenance requirements.

Q: What are the advantages of static wedge wire screens over mesh screens?

A: Static wedge wire screens provide higher strength, customizable slot sizes, and better resistance to abrasion. Unlike mesh screens, their rigid structure minimizes deformation under pressure, ensuring long-term reliability.

Q: How to maintain a static wedge wire screen?

A: Regular cleaning with water or air backflushing is typically sufficient. Inspect for debris buildup or slot blockages periodically to maintain optimal performance and extend the screen’s lifespan.