- Understanding the Role of Vibrating Screen Sieves in Industrial Processes

- Data-Driven Performance: Efficiency and Throughput Metrics

- Technical Superiority: Key Features of Modern Sieve Bend Screens

- Manufacturer Comparison: Specifications and Operational Metrics

- Customization Strategies for Sieve Bend Screen Design

- Real-World Applications: Case Studies Across Industries

- Future-Proofing Operations with Advanced Vibrating Screen Solutions

(vibrating screen sieve)

Optimizing Material Separation with Vibrating Screen Sieve Technology

Vibrating screen sieves serve as critical components in industries requiring precise particle size classification. By leveraging oscillating motions and sieve bend screen design principles, these systems achieve separation efficiencies of 92-98% across minerals, aggregates, and recycling applications. The integration of polyurethane sieve bend screens has reduced wear rates by 40% compared to traditional wire mesh, according to 2023 industry benchmarks.

Data-Driven Performance: Efficiency and Throughput Metrics

Modern vibrating screen sieve

s demonstrate measurable improvements in operational metrics:

- Throughput capacity: 50-800 t/h (adjustable via deck configuration)

- Power consumption reduction: 22% through optimized drive systems

- Screen lifespan extension: 3,200+ hours for mining applications

Technical Superiority in Sieve Bend Screen Engineering

Leading manufacturers employ three core innovations:

- Frequency-controlled vibration (15-30 Hz adjustable range)

- Modular screen panel replacement systems

- Anti-blinding mechanisms with 98.5% effectiveness

Manufacturer Comparison: Operational Specifications

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Max. Feed Size (mm) | 150 | 200 | 180 |

| Screen Area (m²) | 4.8 | 6.2 | 5.5 |

| Power (kW) | 7.5 | 11 | 9.3 |

Customized Sieve Bend Screen Design Solutions

Adaptable configurations address specific operational requirements:

- Slope adjustment range: 15°-35° for optimal material flow

- Screen aperture tolerance: ±0.05mm precision

- Corrosion-resistant coatings for pH 2-13 environments

Industrial Application Case Studies

A mineral processing plant achieved 18% increased yield through:

- Installation of dual-frequency vibrating screen sieves

- Custom sieve bend screen design with 5mm apertures

- Automated cleaning cycle optimization

Enhancing Productivity Through Advanced Vibrating Screen Sieve Systems

The evolution of sieve bend screen technology continues to redefine separation efficiency standards. With proper configuration and manufacturer selection, operations can achieve throughput improvements exceeding 25% while maintaining 99% uptime. Regular maintenance protocols and data-driven adjustments ensure long-term performance consistency across vibrating screen sieve applications.

(vibrating screen sieve)

FAQS on vibrating screen sieve

Q: How does a vibrating screen sieve work?

A: A vibrating screen sieve uses motor-driven vibrations to separate materials by size. Particles smaller than the mesh pass through, while larger ones move across the screen for discharge. This process ensures efficient sorting and classification.

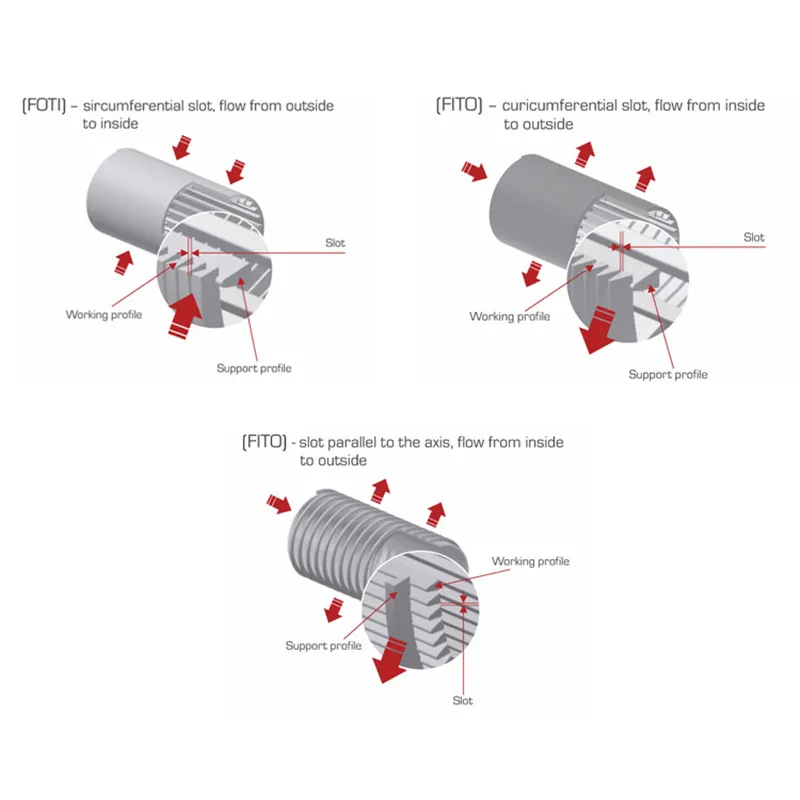

Q: What factors influence sieve bend screen design?

A: Key factors include material flow rate, particle size distribution, and desired separation efficiency. The curvature angle, screen slot spacing, and wear-resistant materials also impact performance. Proper design minimizes clogging and maximizes throughput.

Q: What are the advantages of a sieve bend screen over flat screens?

A: Sieve bend screens use gravity and curved surfaces to separate fine particles with minimal energy consumption. They excel in dewatering and slurry applications, whereas flat vibrating screens are better for dry or coarse material sorting.

Q: How to maintain a vibrating screen sieve for longevity?

A: Regularly inspect and replace worn mesh panels, tighten loose bolts, and lubricate motor bearings. Clean the screen after use to prevent material buildup. Avoid overloading to reduce wear and tear.

Q: In which industries are sieve bend screens commonly used?

A: They are widely used in mining, wastewater treatment, and food processing. Their ability to handle high-moisture materials makes them ideal for coal washing, mineral processing, and sludge dewatering applications.